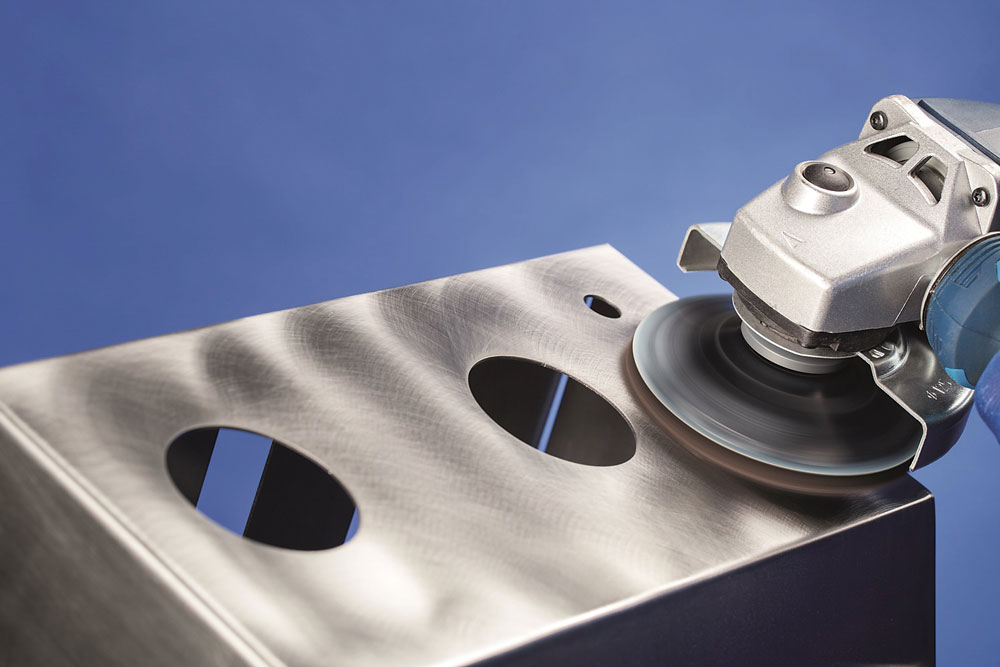

Sheet Metal Finishing

Anybody who knows any metal fabrication process is not a stranger procedure of applying specialized finishes to manufactured metal products. Most manufacturers use different ways to apply finishes to metal products for many benefits. For instance, metals in their ordinary means nature are always exposed to so many elements like water and moisture. These elements when exposed to metals they may corrode the metals reducing their life as well as appeal.

For this reason, it is essential to look into ways of protecting the said metals from these threatening elements. This is why it is essential for you to finish metals so as to protect them from any such threats in the days to come. One of the most wildly used pieces of metals is sheet metals. The significance of this piece of metal is what makes it very famous among the other types of metal products. For instance, sheet metal comes with so many uses in many like forming motor vehicle bodies among others.

However, sheet metal just like any other or the other types of metals is not immune to corrosion and other forms of threats. For this reason, it is only that sheet metal is finished properly to make it durable as well as long-lasting. This way, the metal will be most ideal for use and will last the longest period of time without corroding. However, it is not just the Sheet metal finishing that matters but rather it is how this process is carried out that matters most.

For this reason, if you are planning to carry out this process you need to make sure that you do it and do so in the right way. The finishing process has to be done in the best way most preferably by a top expert who understands this process so well.

The process of sheet metal has evolved over a period of time. This is one process that started a long time ago and has since grown since then. It is one of those processes that are evolving as manufacturing evolves. The same way sheet metal was finished a long time ago is not the same way this process is carried out now.

As technology creeps so do the sheet metal finishing tactics. People in this sector are trying their level best to try and come up with more efficient and proper ways of finishing sheet metals and sure enough, they have. Today there are better ways of coating sheet metal as we shall see in the text below.

The importance of sheet metal finishing

You might be wondering is it really essential to do sheet metal finishing, better still someone may ask is it really necessary to carry out this process. Well, for people to invest heavily in this process then it is because this process comes with so many benefits.

We are going to look at some of the benefits of this process and see why it is essential and necessary to carry out the process of Sheet metal finishing. Just as you may ask the process of Sheet metal finishing comes with so many benefits like the following.

Improved sheet metal appearance

Everyone can agree to the fact that unfinished sheet metal is not something that anyone would enjoy seeing. In fact, this one type of metal that is less appealing if not well finished. As we said, there are so many ways of finishing sheet metals.

In most cases, these finishing methods and tactics are based on the demands and preferences of the clients. If you need an appealing look on your sheet metal then you can request that and you will get it right away. You only need to talk to your manufacturer or the person carrying out the fabrication process for you.

Once you do this, they will allow you to choose the most appealing finish on your sheet metal. This way, you will end up with the most appealing sheet metal finish of your choice. If you need some sharp edges as well as a smooth finish then you will be able to get that right away. You can get a glossy finished product that will meet your appearance finishes.

Increased resistance

The other and by far the main benefit of sheet metal finishing is increased resistance. As we said at the beginning, any piece of metal is always exposed to some of these destructive elements. Water and moisture are among some of these destructive elements that we are talking about. Other than that, we also have bad weather as well as other harsh climatic conditions. If sheet metal is exposed to these conditions then it will definitely not last a long period of time. Finishing sheet metal is the most ideal way of protecting it from these destructive elements.

However, it is also important you know that only finishing sheet metal in the right way will guarantee protection from these elements. There are so many ways of finishing sheet metals but for the best results, you need to look for the best that will serve this purpose perfectly.

Smooth cleaning

Sheet metal is used in making so many products in many areas. Some of these products require some regular cleaning like home appliances among others. It is this cleaning that many people do not prefer doing because of the hardship that comes with carrying out the same process. Cleaning unfished sheet metal comes with so many procedures as well as detergents. It is surely one of those tasks that no one would like to attempt due to its complexity. However, the case is very different from cleaning finished sheet metal.

The finished sheet metal is smooth and so easy to clean. All you need to do is wipe and that will be all, nothing more like it is the case with unfinished metal. If you are looking for a metal that will not give you cleaning nightmares then you need to look for well-finished sheet metal.

With this type of material, it will be easy for you to clean and keep it looking tidy as you many people prefer. Basically, these are some of the reasons that make it necessary to finish sheet metal. As we said, there are so many ways of carrying out this process with different effects as well. We are going to look at some of these ways that are used in carrying out the finishing process. Please note that these Sheet metal techniques are only the best but we have many others.

Electropolishing

This one of the best Sheet metal finishing methods During this process, the piece of sheet metal is dipped into the chemical bath. This process is so similar to the passivated finishing which is also one of the best ways of finishing sheet metal as we shall see later on.

The only difference between this method and the passivated method is that during this process the chemical bath is direct to the DC power supply. Once this happens an electric current is run through the bath dissolving the top layer of the sheet metal.

Passivated finishing

This process works by exposing metal alloys to a nitric chemical bath. When this happens, the iron the sulfuric contaminants on the surface of the sheet metal gets stripped away. This process leaves the surface with a very unique smooth surface that is more resistant to corrosion.

In most cases, this type of finishing is used as a fast step in preparing stainless steel for coating using other materials. However, it is used as a perfect way of finishing sheet metal. In fact, many experts consider this to be one of the best ways of finishing sheet metal.

Sheet metal is such an essential piece of metal used in many areas for various purposes. Before ending up with a proper piece of sheet metal you need to look for the right machines that will help you with this process you need to reach out to Contract Manufacturing Specialists of Indiana, they have the best metal fabrication machines.

There are so many things that make us be the best contract manufacturing company in the region. The top among them all is the kind of experts that we employ. We have a team of highly talented experts that will work on your project.

Our core offerings and services at Contract Manufacturing Specialists of Indiana includes, but is not limited to, the following below:

We service multiple cities throughout the state of Indiana. We provide all the services listed above, and much more in every city throughout Indiana.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.