Laser Cutting Design

Technological advancement has seen the development of several useful devices and systems. Our life as human beings has become easy and smooth. Tasks that were very difficult in the past are now easy with the aid of these useful systems and devices.

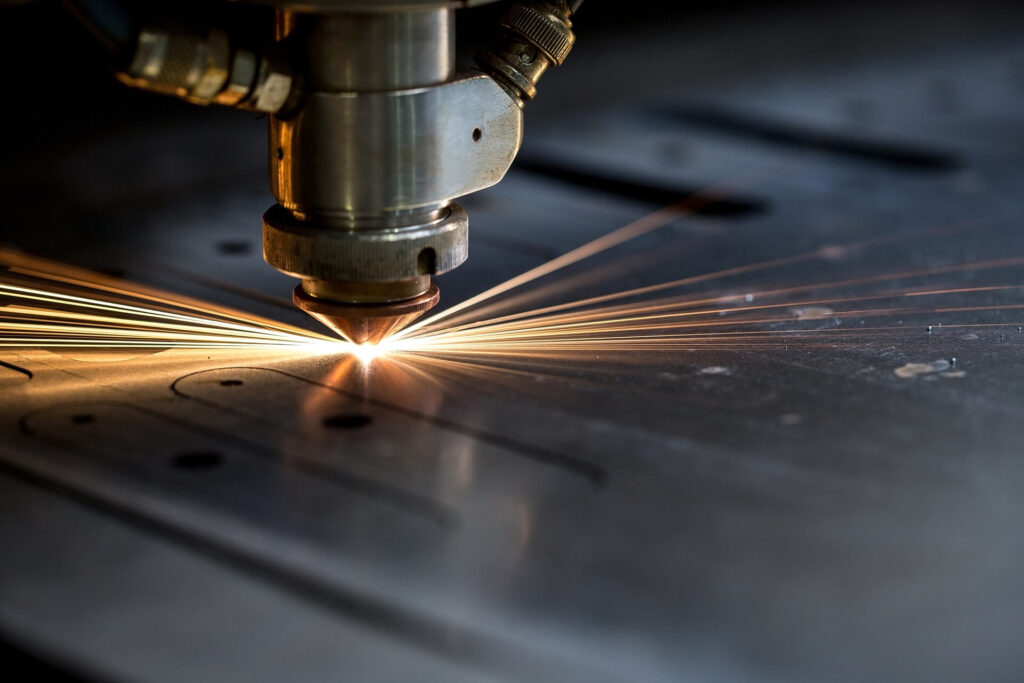

Laser (Light Amplification by the Stimulated Emission of Radiation) technology is among the greatest inventions. The laser device generates highly concentrates monochromatic and coherent light beam. It makes use of stimulated light emissions that are produced. One of the companies that make good use of this technology is Contract Manufacturing Specialists of Indiana.

This technique is widely used in the industry of metal fabrication to increase cutting capacity, increase productivity, improve the cutting quality, increase cutting speed, capacity, and reduce the cutting cost. This technology utilizes a laser to cut different types of materials. Some of the common metal for cutting laser include stainless steel, copper alloys, carbon steel, and aluminum materials. You can cut virtually any type of metal material using this great technique.

There are various types of laser cutting procedures that are used in Indiana. Laser cutting is among the most common and popular techniques for cutting metals. It is advantageous than any other procedure that is used to cut materials. However, like any other process, laser cutting also has its own set of setbacks. However, when you compare these disadvantages to the benefits, they are insignificant. The main advantages of laser are cutting precision, quality, cutting speed, and economy. One of the main drawbacks of this process is the high voltage requirement.

The laser bean can lead to very serious burns. It is among the main drawbacks of this metal cutting procedure. With this procedure, you will be able to produce highly-concentrated beams of light. It can apply energy to a minute area quickly. The best part of it is that you can control it by mirrors and lenses and essentially as light. The other great thing about laser is that it travels at a very high speed. It can travel in an empty space and transmit information in a straight line.

With the great properties that laser technology has, people are now using it for several applications. The main application of this technology is to cut metals. Laser cutters utilize huge energy amounts when working. You get a cut by moving a laser beam across the surface or by moving the object that you are cutting.

Industries that need sheet metal designing and fabrication use laser technology to make the process easy. Availing the services of a trustworthy laser cutting service is the best way forward. There are several laser cutting services in Indiana and all of them claim to provide the best service. However, you have to make sure that the company is reputed and reliable before leaping. The best brand in this case is Contract Manufacturing Specialists of Indiana.

There are various forms of laser cutting that you can use to cut metals. Among the laser cutting techniques, the most common one is CO2 or carbon dioxide laser. It is a gas laser that is widely used in welding.

Laser cutting is a 2D technology because light travels in a single direction at a time. The process needs a deconstructed and simplified production approach. Laser cutting calls for a digital 2D vector drawing that we call laser cutting design. You can think of this as the route or stencil that the laser will follow while cutting the metal.

There are so many 2D vector drawing programs in the market. They range from CAD engineering software, online applications to professionals. regardless of the program that you are using to create your file, the most important thing is the ability to export the file in the most suitable products.

Contract Manufacturing Specialists of Indiana prides in providing you with custom laser file engineering and preparation services. However, if you are thinking of producing your individual file for laser cutting, you need to follow a few tips. Some of the laser cutting design tips include;

Close the Edges of Your Design

The laser machine cuts along the outlines in the metal. As a result, all the places you wish to have free or open from metal required to be fully surrounded in a closed and complete contour. For example. If you need a circle laser cutting out of sheet metal, the arc in the circle has to be a fully connected circle. Even tint breaks in the lines can lead to a would-be cutout remaining attached to your sheet metal as accidental tabs. Using tabs and notches, you can maintain the structural integrity of your laser cut metal piece.

Mind Your Notches and Metal Tabs

Laser cutting relies on notches and tabs heavily. When you get them right, you will maintain the structural integrity of the metal plate or sheet as you produce the product. A rule of thumb for the metal notches is that the minimum notch width should be the thickness of the material or 1mm whichever is greater. The length should not exceed five times the width. The minimum distance between the notches should be 3mm.

The thickness of the metal tabs should be at least 3mm or twice the thickness of the material whichever is bigger. At all times, the length should be five times less than its width. The minimum spacing of the tabs should either be 1mm from one another or equal to the thickness of the material, whichever is bigger.

Identify the Thickness and Depth of the Line

As you submit your file, distinguish and clarify the meaning of each style of line. Laser cutting can do everything from wide etching to hairline deep cuts. You have to make sure that the file distinguishes and you communicate your intended cut and etch clearly. Also, communicate the depths or widths that you expect to do either of them.

Accordingly, Plan for Precise Laser and Holes

If you want holes that have high tolerances, the best practice is using the laser cutter to etch and pierce the specific hole location. From here, you need to use a bit to drill the holes directly. It is the best way to get accurate results for threaded holes. Lasers heat and melt the steel material but when you drill into cold steel, it will make sure that you have a flawless final product. The diameter of a pierced guide hole should be naturally smaller than the final hole that you intend to produce.

Decide on the Sharp Angles and Rounded Metal Corner Fillets

Sheet metal parts often come with sharp corners. To more safety, you can add rounded corners (fillets) to the otherwise sharp corners. The thickness of the fillets should be at least half the materials’ thickness. Whether you want sharp corners of safer corners with fillets, be keen to mark them in your file or discuss with the laser cutting design professional.

Lay Out the File for Thin Features and Multiple Parts

As you cut parts on the same metal sheet, you should leave a distance that is at least the thickness of the material between them. If you place the parts too close to one another or cut very thin features, you will be risking burning away the materials that are between the two cutting lines. It is wise to outline all the pieces as a whole instead of using the lines between the two pieces to share cuts.

Get the Format of the Laser Cutting File Right

Most laser cutting design experts work with .dwg and .dxf files. Professional programs such as the Adobe Illustrator, Draftsight, Inventor, SolidWorks, and AutoCAD among others are used to generate these vector files. We also have an endless list of online applications and software programs that convert PDF, .svg, .eps, and other file formats into .dwg and .dxf files. Once your .dwg and .dxf file is ready to go, that is great. If not, Contract Manufacturing Specialists of Indiana is willing to work on the laser cutting design from scratch. All you need to do is contact the team for help.

There are so many things that make us be the best contract manufacturing company in the region. The top among them all is the kind of experts that we employ. We have a team of highly talented experts that will work on your project.

Our core offerings and services at Contract Manufacturing Specialists of Indiana includes, but is not limited to, the following below:

We service multiple cities throughout the state of Indiana. We provide all the services listed above, and much more in every city throughout Indiana.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.